Custom-made Constant Force Springs

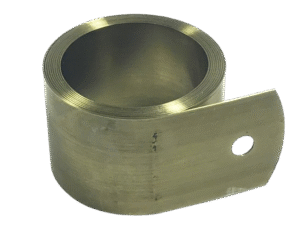

Constant force springs are manufactured from pre-tensioned flat spring material, coiled into a spiral with each revolution tightly wound upon the next.

. Thanks to the tightly twisted windings, the spring always wants to return to the same position. The force is pressed by this “presetting” on the last turn. Because of this, the force of the spring does not start at 0 as usual, but at a finite value. As a result, the constant force springs achieve the named constant force. There may be slight variations around the initial position of the constant force spring.

Production of constant force springs

Constant force springs are made from a mold. The leaf springs are turned in such a way that they sit against each other. The production process of constant force springs is carried out with the utmost precision by our machines. After production, the springs undergo the usual multi-level quality control where parameters and forces are checked to ensure that the springs are adjusted to the correct specifications. The production of Crownhook starts from 50 pieces with the corresponding mold. Without a corresponding mold, it can be economically unprofitable to order custom-made constant force springs.